Tutorial: Choosing a Benchtop Leather Splitter

I have prepared this tutorial to answer many of the common questions I receive on the pull-through leather splitters.

The first question to answer is what types of leather can be easily split with a bench top splitter. The leather needs some body. Vegetable tanned leather, latigo, English bridle leather, harness leather and tempered rawhide all will split well. Softer leather tend to stretch, compress, and not get a “bite” into the splitter blades well so soft chap leather, upholstery, and similar leathers will not reliably split with a bench top splitter.

There is some confusion in terminology. Skiving and splitting can be used interchangeably by one person and be two or three separate things to another. Then some use a mixture of both. I call splitting to be reducing the thickness of an entire piece of leather. I consider skiving to be reducing a section of the leather. “Level skiving” would be to reduce the thickness of part of a strap – as in reducing the thickness at a fold area on a belt and then it is carried out even thickness to the end of the strap. If you taper the thickness to the end of a strap out to a feather edge, most will consider that to be lap skiving or tapered skiving. It can be used to reduce the bump where the end of the strap would be folded over a buckle or ring. Lap skives can also be used to join two pieces of leather end to end and make a joint with a minimal to no bump.

Width of blade is another area of common questions. To back up, most of these splitter designs came from an era when harness and saddlery were the major uses of leather. They were designed for strap work. Most people can split up to three inch widths without much of a problem. At wider widths than that then it gets more difficult to pull the leather through. The advantage of wider blades is that you have more blade to work across before you need to strop or resharpen the blade. You can split one strap on the right side of the blade, the next strap in the middle, one on the left and so on to maximize the use of the blade.

Next comes the question as to which type of splitter is most appropriate. Some are good for splitting or level skiving, but won’t do a reliable lap skive. Some are good at lap skives but a bit unwieldy for splitting. Some can do splitting, level skiving, and lap skives. So then, which style is best? My quick answer is they all have advantages and each will have some disadvantages as well. I will go through the more commonly seen and give my thoughts,

CS Osborne #86 Splitter

First off, we will consider the CS Osborne #86 splitter. These have widths commonly found from six to eight inch widths. You will occasionally see some outside these sizes, but these the usual sizes found.

This particular pattern has been continuously made for over 120 years. They were Army issue for a few wars, and still made today with few changes. The advantage is they are compact and simple. They mount to the edge of a bench, can be mounted on a block and held in a vise, and have the smallest footprint for a splitter. The thickness of the split adjusted by a large thumbscrew that raises and lower the roller. The only adjustment is two screws in front of the blade that sets the roller position in relation to the blade edge. They are the simplest splitter to adjust, and as a bonus usually are among the lesser expensive splitters to buy new or used. Disadvantages come too. They will not do a lapskive with some sort of a jig. The blade edge is exposed in use. They bear watching and merit good safe work habits. After use the roller can be raised up to meet the blade edge and minimize the chance of a cut.

There is no scale for thickness adjustment, they are set by experience and testing a scrap. The other downside is that a strap can occasionally flip up and will “ride the blade bevel” and chop off. That is eliminated by making the sure the pull through the splitter is downward from the level of the roller and the strap yet to be split is down lower than the roller in front as well. If the blade and roller are not parallel, this can be corrected by placing a shim on the lower side between the blade and frame.

CS Osborne #84 Splitter

CS Osborne #84 splitter is another commonly used splitter, and there have been several knockoffs.

These have handle that adjusts the thickness of the split. That makes them versatile for splitting, level skiving, and lap skiving. They are also quite simple to adjust. The roller is fixed in place and the blade has slots for the hold down bolts. The blade is set in place with the edge in proper relationship to the roller and the bolts are tightened down. They do lap skives by pushing the handle forward (raising the roller) with your left hand as you pull the leather through with your other hand. They do have a scale for thickness and an adjustable stop for repeated leveling. You could write down a scale marking and go back to that same position a few weeks later and be very close. They have a flip down rod in front of the blade to act as a somewhat guard. It also helps to hold the leather and avoid flipping up and chopping as can happen with the #86 style. Disadvantages are that still the leather can ride the bevel and chop occasionally if you are not attentive to direction of pull and feed. They are a tried and true pattern that was made for quite a while and then dropped by Osborne. In the last few years CS Osborne has reintroduced with some minor changes. If the blade and roller are not parallel they can be easily corrected with a shim between the lower end of the blade and the frame. This pattern splitter was made in the early years by Randall (Keystone), HF Osborne, and CS Osborne. It has been made in similar versions the US as well imported and sold by other suppliers.

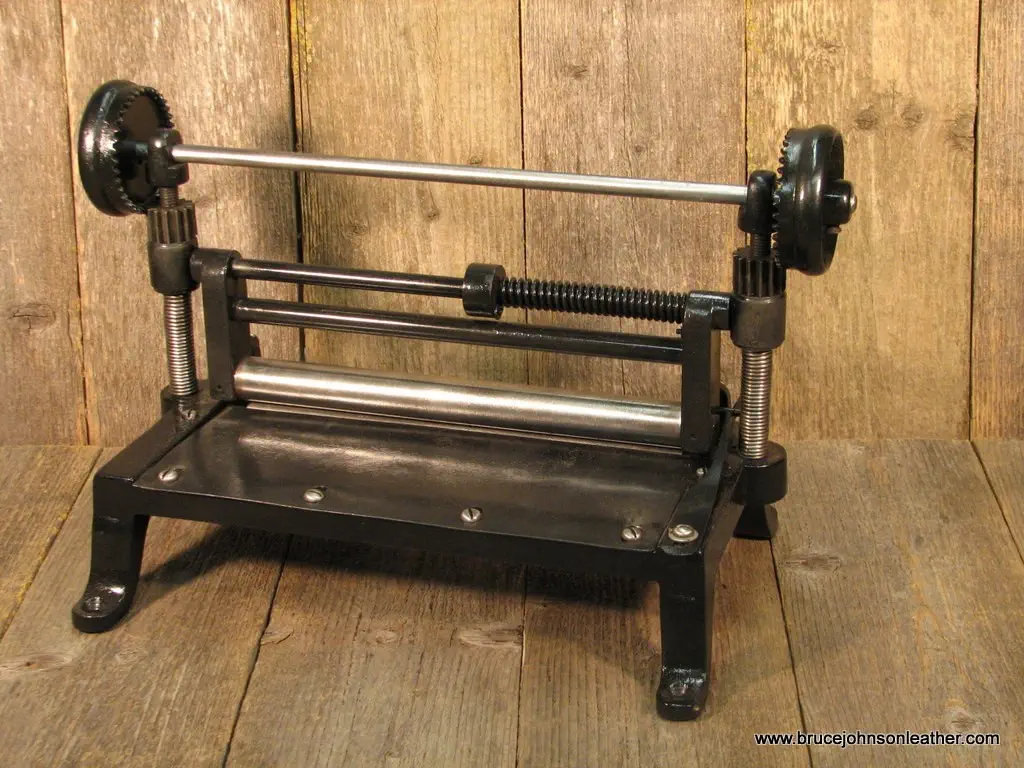

Chase Pattern Splitters

Chase pattern splitters are another commonly found splitter. They look a little (or a lot) different than most other splitters. Makers of them include JW Chase, Horn, Hansen, CS Osborne, HF Osborne, and Randall and likely a few others. They have a larger footprint than other splitter of a similar size. There are two connected adjustment knobs at the top that raise and lower the roller to adjust thickness of the split. The leather is put in grain side up and the split comes off the bottom. This is opposite of most other splitters. They will do level skiving and splitting but not lap skiving. They have a few advantages. There is a top roller and bottom roller. The top roller sets the thickness of the finished split and the bottom roller helps insure the leather feeds squarely into the blade. This prevents the leather from twisting or flipping up and chopping off. They can be leveled by easily without shimming the blade by sliding off one adjusting knob, turning the gear on the affected side until parallel, then repositioning the adjustment knob. When not in use the blade edge is not exposed. They do some with disadvantages. There is no scale for repeat splitting so it is set by testing on scrap. There are several adjustments that can be made, and that can make things a bit more complicated. There is the up and down to set the thickness of the split. There are two adjustment screws that set the relationship of the top roller vs. the blade edge. For the bottom roller there is a series of screws on the plate that allow front to back positioning of the bottom roller vs. the blade. Finally there are two adjustment screws that set the spacing between up and down between the bottom roller and the blade. With this many adjustments, there are more complicated than a #84 or #86 splitter. Once adjusted properly, they are choice of many leather workers and braiders.

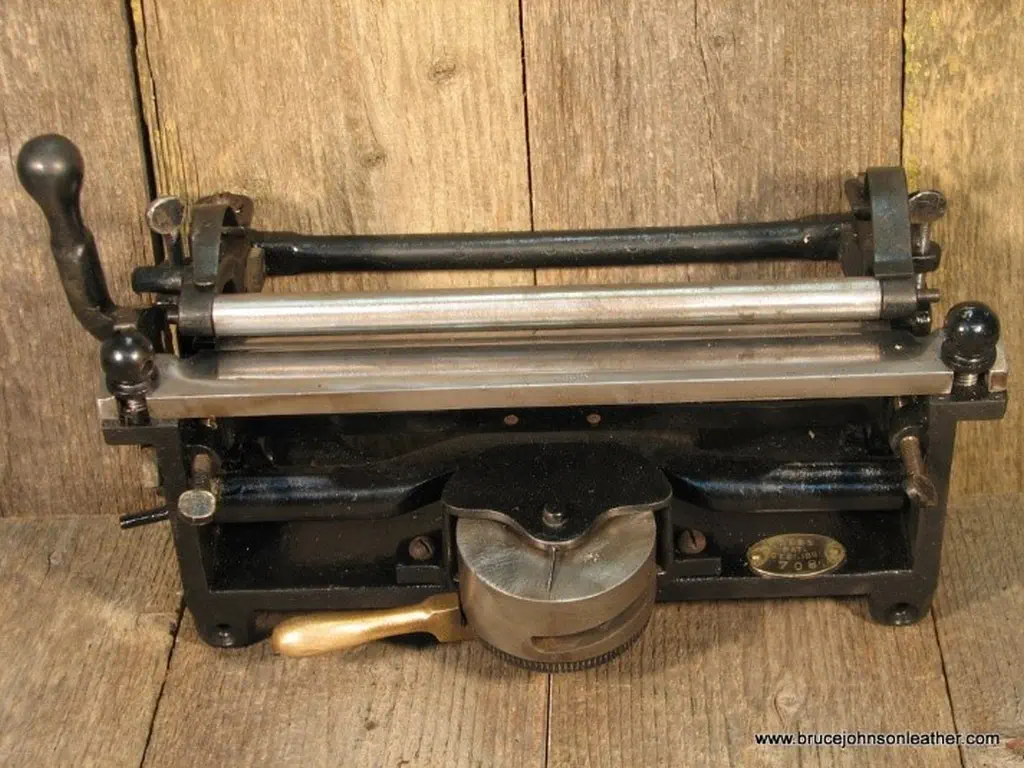

Krebs Pattern Splitters

Krebs pattern splitters are a bit less common. They were originally made by Krebs in Cincinnati, OH and later made by Randall and CS Osborne. Krebs pattern splitters mount on the edge of the bench. They come with several advantages. First and foremost they have a lever adjust with a dial type scale. They are very good for repeatable splitting. They will do splitting, level skiving, and some people can move the lever as they pull the strap through and do nice lap skive too. They split with the flesh side up similar to the #86 and #84 splitters. They have two rollers like the Chase splitters. On the Krebs the bottom roller sets the thickness desired and the top roller helps feed the leather squarely into the blade. The blade edge is protected by its position between the two rollers and not exposed. They carry some of the disadvantages of the Chase pattern splitters in that there are several adjustment points. Once properly adjusted they are “Cadillac of splitters” as described by some. They tend to not be found as often and are usually expensive.

Spitler Pattern Splitter

Spitler pattern splitters have a plier type handle that binds on a ring. You grip the handle and partially squeeze the handles to release the bind. You can push forward to adjust the roller up and down to control the thickness of the split. They have some advantages. The ring has a scale on it and there is also a stop screw to set how far the roller can come up for repeatable splitting. There is also a rod in front of the blade edge to somewhat protect the edge and also keep a strap from flipping up. They will do splitting, level skiving, and make a nice lap skive. They come with some inherent disadvantages. The plier handle must make a good bind on the ring to hold its position when released. If the edges of the slots are rounded a bit or the handle spring is weak the handle can shift in position while pulling the leather through. The roller is moved by two eccentric discs using a cam action. These are connected by a square rod. One problem can be if the rod has twisted the cams are not synchronous and the roller will not be parallel with the blade. If they are tight and good, they are a nice versatile splitter. Even if the handle doesn’t get a good grip on the ring when released, they are always a good lap skiver.

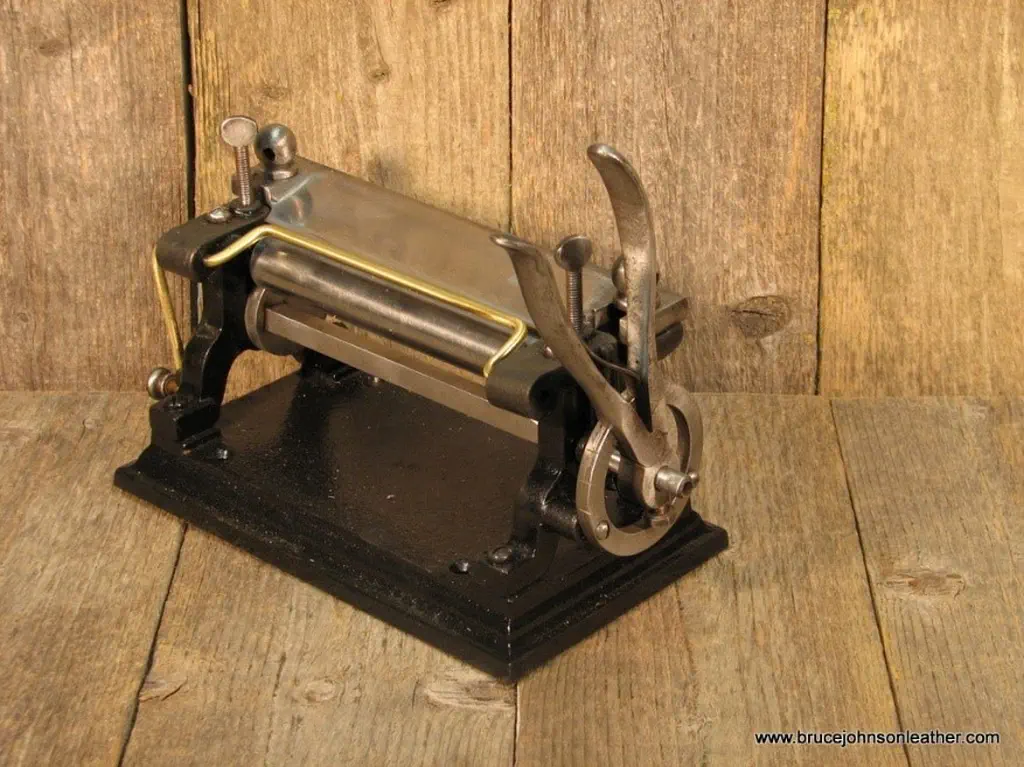

Wood Bottom Splitter

Wood bottom splitters are also fairly rare. They were made by CS Osborne and called the model #87. These are used for splitting, level skiving, and with a bit of practice make a lap skive as well. The wooden base screws down to the bench. The handle on the adjustment beam is slid to one side to open the gap between the roller and blade edge. The leather is inserted and the handle slid back as the leather is pulled into the blade. There is a set screw that can used as a “stop” to control the thickness of the split. If this screw is backed off to allow the blade and roller to meet, then you can do a lap skive out to a feather edge. They are simple to adjust. The blade has forward and back slots and you slide the blade into the proper position relative to the roller and tighten it down. The set screw controls the thickness. They are really just that simple. Disadvantages, they don’t have a scale. They are not commonly found.