Tutorial: Osborne #86 Leather Splitter

Set up – The Osborne #86 leather splitter is designed to be mounted on the edge of a workbench with the adjusting thumbscrew hanging over the edge. Some people mount them on a bock of lumber like a 2x6 and then clamp the board to the bench. One caveat for doing this is to make sure there is enough clearance to operate the thumbscrew.

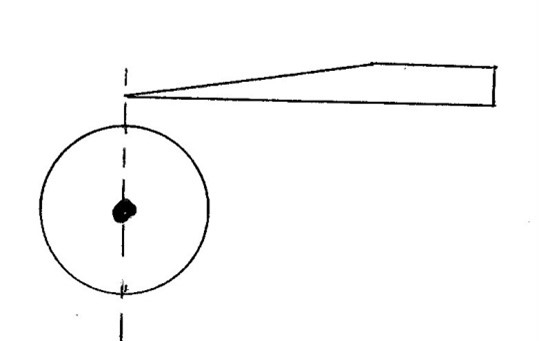

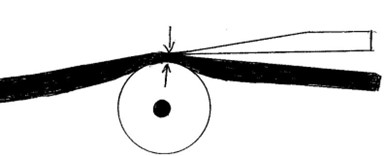

Adjustments – The #86 has two adjustments. There are two screws on the front of the splitter that set the roller position relative to the leading edge of the blade. These screws are adjusted equally on both sides. Ideally the dead center top of the roller should be even with the leading edge of the blade when viewed from the top.

That said, some people may find after some use they prefer the roller slightly behind the blade edge.

If the blade is too far forward the leather may tend to slide under the edge of the blade and not split.

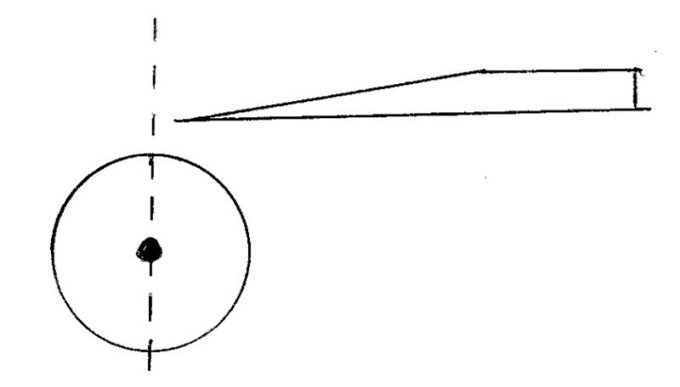

The other adjustment on the #86 is the large thumbscrew on the back of the splitter. This thumbscrew is dialed up and down to control the height of the roller and subsequently the thickness of the finished split.

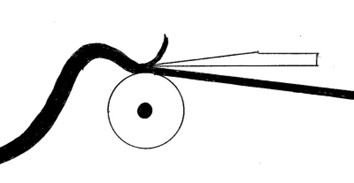

Using the #86 – There is a thumb lever on the left side forward of the blade. That will move the roller forward and open the gap between the leather and the roller. The leather is inserted into the gap from the back of the blade.

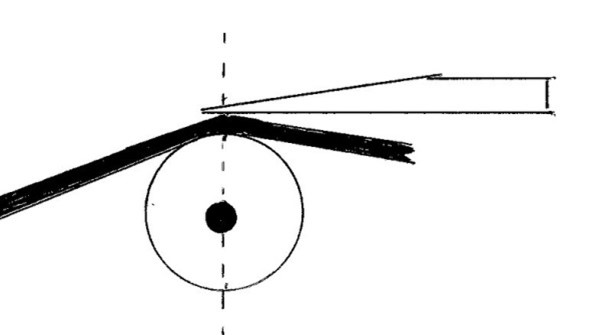

You then start to pull the leather through as you release pressure on the thumb lever. This will allow the roller to ease back under the blade and start a nice tapering of the cut into the leather.

The leather is continued to be pulled through with the thumb lever released. For even splitting a whole strap, I will split about half the length starting in the middle, then reverse the piece, reinsert it and and split the opposite direction.

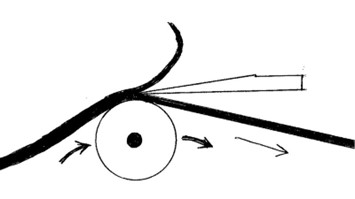

In use, the direction of the pull needs to be below the level of the top of the roller. This will ensure the leather is meeting the blade at a consistant angle and split evenly. If you are pulling upwards the entire thickness of the leather can be pulled into the blade and the piece chopped off. The leather being fed into the splitter likewise needs to be below the level of the roller. For wider straps they generally will lay flat and not need to be held down. Narrower straps or lace may tend to twist and flip, especially long pieces.

They can flip and be pulled into the blade and chop.They need to be held below the roller level and fed flat to ensure even splitting and not being chopped.

It is also helpful to use the entire width of the blade. Even though the blade width is 6 inches and some models more, most splitting is done on narrow straps and belts. The natural tendency is to use the center of the blade. It wears faster and needs more frequent resharpening. I try to use the whole width. Left side on one strap, right side on the next, then center, etc. I spend less time resharpening one section that way.

Safety – The blade is sharp. The blade is exposed. Be aware of the blade edge. . You just need to be aware of that blade edge, especially reaching over them. . There are several leather tools with exposed blade – draw gauges, plough gauges, French edgers, and all manners of knives. Paying attention to where that blade is all it takes to be safe. Do not feed leather into any blade pushing it by hand - ever. For a long piece you can lay it out in front of the blade and open the gap if you pay particular attention to where your hand is in relation to the blade edge. Feed enough through to get a good grip and then pull it through. Then turn the piece around and pull the shorter unsplit section through. On the #86 I will dial the roller up close to the blade edge to protect me from the edge when I am done

Special attention needs to taken when children and people who act like children are present. Splitters look cool and attract the attention of shop visitors. I really don’t know why, but it is a fact. People with no clue about what they are looking have the innate need to pick up a knife and check the edge to see if it is sharp. Splitters will attract those folks like a magnet.

Blade care – these are high carbon steel blades and will corrode, especially with chrome tanned leather like latigo and apron split. The crumbs and splittings need to be brushed off and wiping with a light oil is a good plan if the splitter may not be used for a while. Just like any blade a good stropping every so often helps maintain the edge. Level strokes and not rolling on the edge will maintain the edge. When the blade needs to be resharpened, it needs to be done by someone experienced and preferably experience with these tools. I have seen horror pictures of ruined blades done by profession general sharpening shops. I have seen heavy grit grinding wheels take chunks out and leave waves – these aren’t lawn mower blades. The blade bevel angle needs to be maintained. It is possible to take a blade out to too fine an edge like a razor blade. When that happens the edge can chip out or roll. I take them out to a foil edge (some people call it a wire edge). I strop that off and then put on a secondary bevel at a slightly higher angle. I actually prefer the secondary bevel to be done with a “slack belt”. That edge is more durable because of the metal backing the blade edge. Most good knife makers and cutlery shops understand this. The foil edge on the secondary bevel is stropped off. One note is that splitter blades are a single bevel blade. The bottom needs to be flat. When I strop I try to keep the bottom of the blade pretty flat.

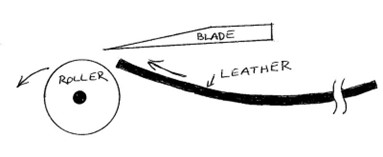

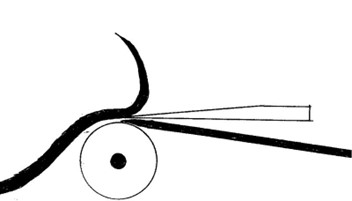

Pet Peeves – The biggest mistake I see is in starting the leather through a splitter, and this applies to any style of pull splitter. The leather needs to be feed into the blade gradually. The thing NOT to do is stick the leather in to bigger gap than you want to split, release the roller to go back into position and THEN adjust the height mashing the leather between the blade edge and the roller.

Yes leather is somewhat compressible and will mash some. You pull and instead of the blade gradually tapering into the leather it dives and can make a divot or uneven split. The bigger issue is the leather is pressing up on the bottom of the blade right at the edge. This can’t be doing that blade edge any good. All pull through splitters have a release so the leather can gradually be fed into the blade. Your splitter and I thank you.