Tutorial: French Edgers

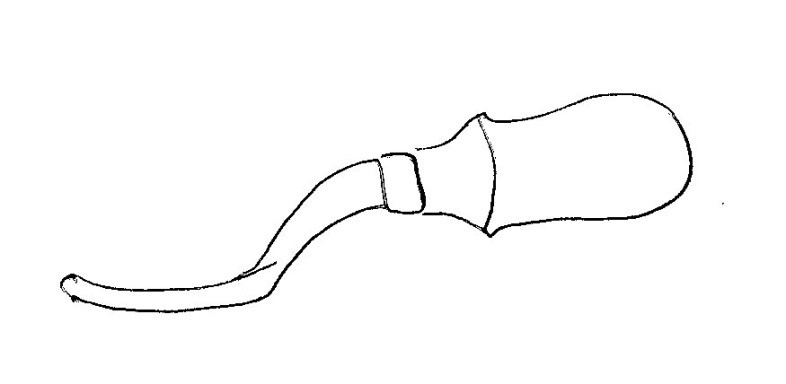

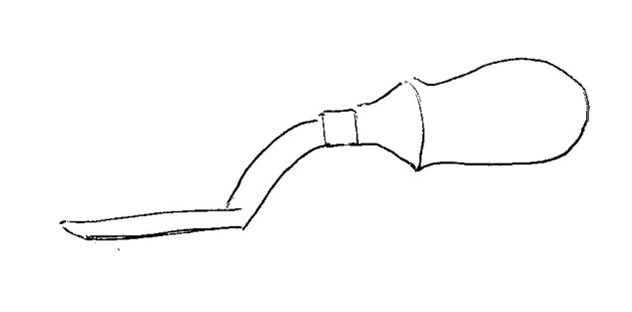

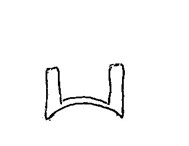

French edgers are used to skive, thin or bevel edges, cut a mitered corner, cut a channel or trim in some areas. They also come in two profiles viewed from the side – flat or with a slight curve or “sweep”. Then to further confuse things, a few makers had them with a round bottom French edger that cut a rounded profile.

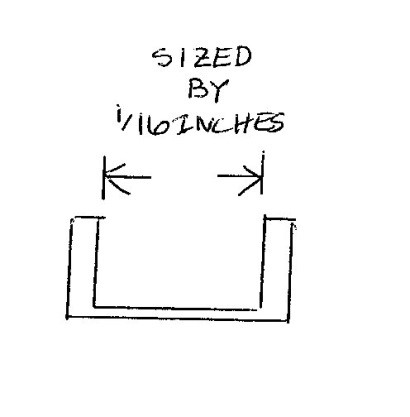

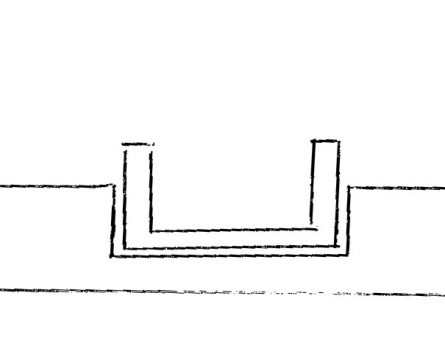

Sizing – French edgers are sized by the width of the cutting edge between the side rails. The common size pattern seems to be that each number is 1/16 inch wide,, i.e. a #3 French edger cuts 3/16” wide.

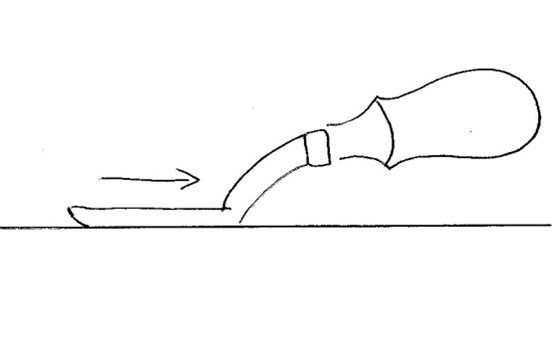

Usage – French edgers are used in a push motion to cut or gouge leather. They are also used to trim excess leather, as with a sewn welt. The key to good results is maintaining a consistant angle while pushing the tool forward. As with any cutting tool, they need to be sharp to achieve the best results as well.

Sharpening – There are a few ways to sharpen a French edger and some are diametrically opposite to achieve the same result. To further compound the issue, there are two kinds of edges on French edgers. Most of the older French edgers were made with a thinner blade stick area and result in a thin edge, much like a thin knife edge. Others are made from thicker stock, flat on the bottom with an angled bevel on the top edge like a chisel.

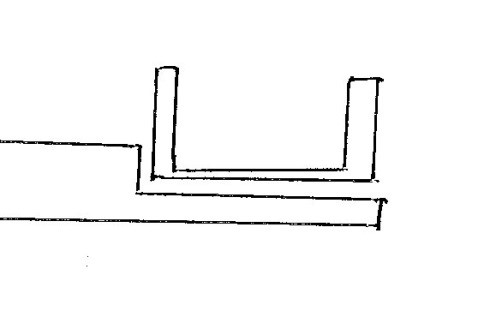

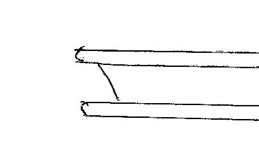

The first thing I do with an as found French edger is to square up the cutting edge. Some may be worn more to one side or the other or be chipped or ragged.

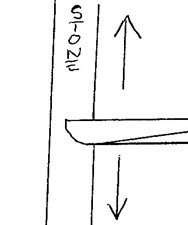

I use a flat sharpening stone or firm piece of material wrapped with wet-dry sandpaper. I hold it vertically to take back the leading edge until it is square across.

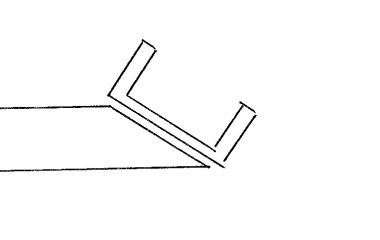

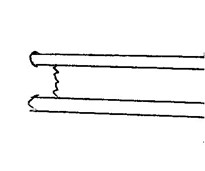

Once I have the square leading edge, then I begin to bring an even bevel across the entire cutting edge. I was taught to mostly work off the bottom. I do that by pushing the tool into an appropriate grit sharpening stone or wet-dry sandpaper on a flat surface. On the curved bottom edgers you need to pay special attention to doing an even stroke and contact on the length of the bottom surface .

This is where there is a totally opposite method. Some people work off the top of the edge. If you can do that and maintain an even angle then by all means do what works for you. I have seen a lot of stubbed off edges though from using too steep of an angle on the top side.

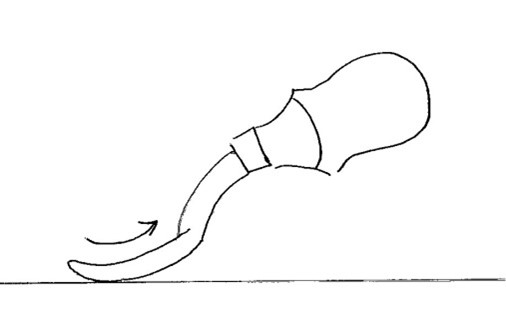

Once I have a good even edge I start to draw the edge. I pull the tool back against a fine grit stone or paper the draw a thin foil edge, working both top and bottom of the bevel. I work the bottom on a fine stone or wet-dry sandpaper and the top on something just as fine that fits between the siderails.

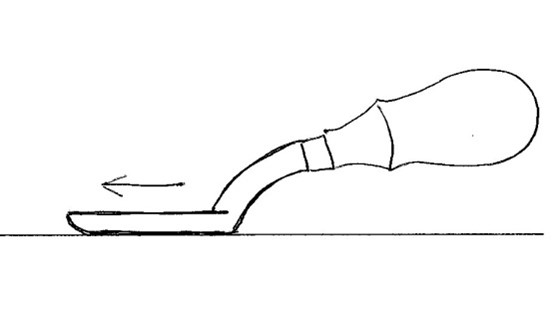

Stropping - Once there is an even foil edge the width of the blade it is time to strop that off to leave a clean and polished fine cutting edge.

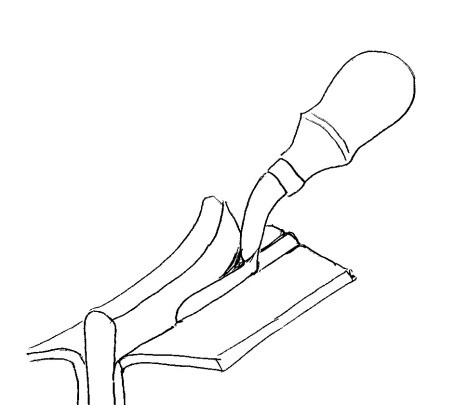

This is where it gets simpler. I use leather strops charged with green polishing compound to strop off the foil edge and polish out the remaining grit marks from the last abrasive. I use two strops. One is my wide strop that I use for knives and wide blades. The other is a strip of firm leather cut the width of the cutting edge. The bottom bevel is stropped by pulling the tool away from the edge of the big strop. The French edger is turned over and the top edge is pulled against the strip to strop that surface. As I get close to the foil edge being totally stropped off. I do a slight upward rolling action at the end of the stroke. That gives me a slight compound convex edge (“Moran edge”) that makes a more durable edge.

A few tricks and cautions

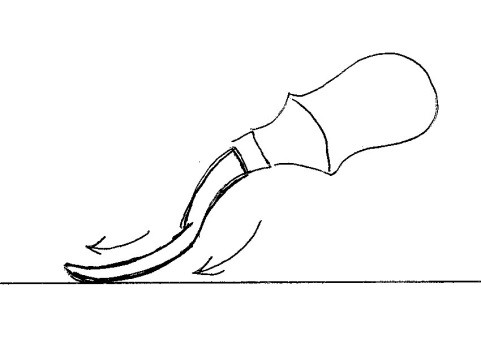

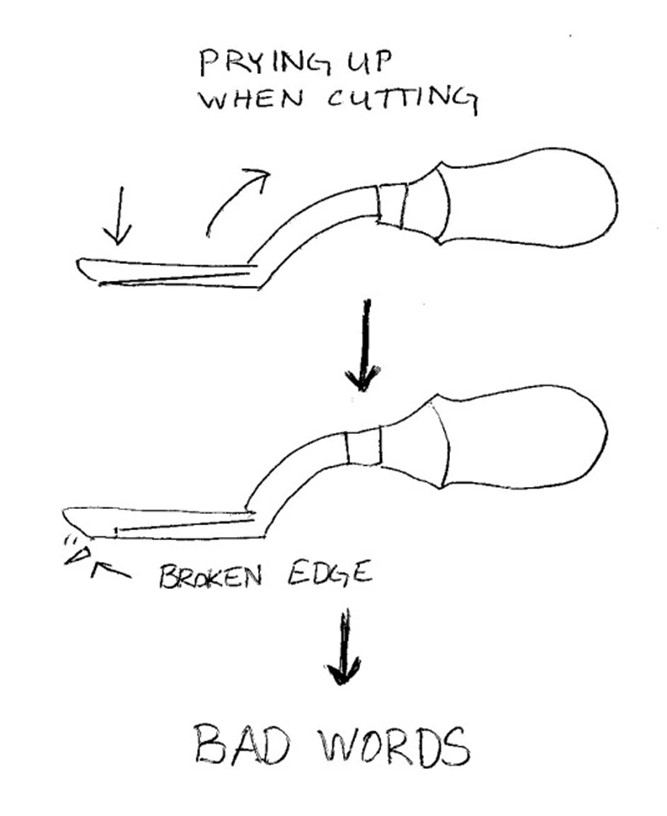

French edgers with a fine edge have a few concerns. The most common damage is causing by not “”following the blade” when pushing as termed by an old friend. This is most common when used in saddle making and trimming a few layers of groundseat to cut a stirrup leather channel. If you try to “cut and pry” to make a sweeping cut you may put a top to bottom pressure on the edge and chip it out. For this type of cut you can do it with a flat bottom French edger if you follow the blade.

The other big concern is maintaining the edge. Strop the edge as you would a knife and the edge will last quite a while. You are cutting a lot of leather with a narrow section of blade and some routine maintenance makes the French edger a friendly and useful tool.